Good news! I found about 1500 square feet of warehouse to do my work in for 2 months @ only $500/month! (I'm sharing an 18,000 square foot warehouse).

I will be moving the boat there tomorrow so I'll be able to update with some progress soon!

The guy next door (other side of the wall in the warehouse) has a forklift I can use, commercial/industrial air with lines all over the warehouse, exhaust system, work tables, power/water included...

Oh, it's a sweet place to do this work for sure!!!

Okay, she is in her new home for her 2-month re-hab stint...

So, first things first... Start pulling that cap. I removed a zillion screws and started prying both the bow and stern:

The cap came off without too much trouble, but there was some foam to remove:

I went from this:

to this:

At least the cap is now removed and I can work on some hull-insides! Do boats always look that much bigger when you look at just the hull?

Here's a shot of the underside of the deck:

Here's what I learned today...

If you have an anchor locker with no drain to the outside, the water will fill up all of your foam.

If you have rod holders that open up to the interior of your hull with no way to drain out, it will fill up your foam with water.

If you have fish boxes in the bow and the drain hoses are broken, they will fill up your foam with water.

Foam is considerably heavier when it is filled with water.

Water soaked foam can and will help a LOT of mold growth in your hull.

Water soaked foam is nasty stuff to remove.

If you think you have a lot of foam on your boat... Think again... I had what your boat manufacturer couldn't fit in your hull! Every bit of space between the deck and hull, hull sides and liner from keel to gunnels was FULL of foam.

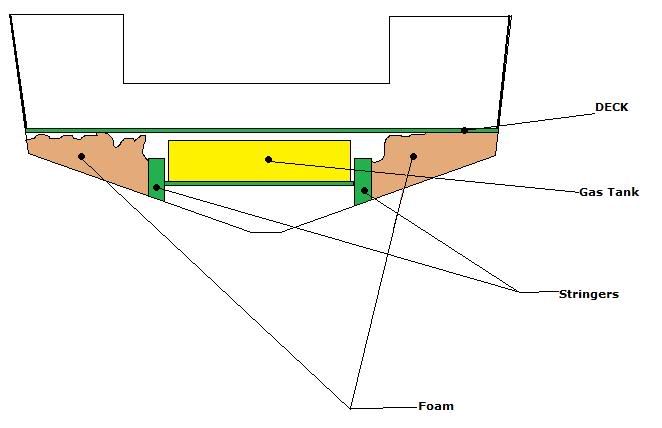

I thought about not going back in with the foam when I put it back together but my deck does NOT rest on the stringers. My deck is pretty stout with a lot of hatches, but having all of that foam in there surely helps support the deck to some extent, and I'm sure it cut down on a lot of sound.

The only problem was not a great design on the anchor locker, rod holders and broken drains.

When I put it back together again, those issues will be solved and I'll be very sure that where there's foam, there will be NO WAY for water to reach it!

Carry on. More reports to follow soon. My next step is to start cleaning and sanding/grinding the inside of the hull for some repairs and a new layer of glass, just to tidy it up.