13' Gheenoe Rebuild

Moderators: bman, Tom Keels, Chalk

Re: 13' Gheenoe Rebuild

CT - Thanks for the info. This gheenoe project has been fun, I've learned a lot, and expect to learn much more before it's finished. I'm going to stick with plywood for this first boat just because it's cheaper to learn with than the foam board and not as expensive when you screw up. Gheenoes are a dime-a-dozen on Craigslist and I'm planning on buying a 15' for my next rebuild. I'll use foam board on it once I've gotten the hang of the fiberglassing, etc.

Question for the pros out there - looking at the last of the pics I posted, does the inside of the boat look clean enough to fiberglass to? I've removed most of the paint / gel coat, but you can see areas where a little paint remains. Do these areas need to be removed or am I good to go with what I've done so far? Disregard the back half of the boat as I'll be setting the deck on top of this area.

Question for the pros out there - looking at the last of the pics I posted, does the inside of the boat look clean enough to fiberglass to? I've removed most of the paint / gel coat, but you can see areas where a little paint remains. Do these areas need to be removed or am I good to go with what I've done so far? Disregard the back half of the boat as I'll be setting the deck on top of this area.

Boom goes the dynamite.

-

charlie tuna

- Posts: 600

- Joined: March 30th, 2011, 7:00 pm

- Location: Fort White

Re: 13' Gheenoe Rebuild

Your new resin will stick to anything, but you don't know what that "anything" is stuck to??? I would take your disk sander and take it down to the glass, grind thyat paint off.

PS: when you use foam and make a mistake, you can just piece in a piece of foam and lightly glass over it, and it remains as strong as ever. You build the entire project with a "hacksaw blade". The urithane is very cheap -- the deckboard is expensive but you have zero waste --just piece it together. I used a product(closed cell) called "Divinacell" 5/8 thick.

PS: when you use foam and make a mistake, you can just piece in a piece of foam and lightly glass over it, and it remains as strong as ever. You build the entire project with a "hacksaw blade". The urithane is very cheap -- the deckboard is expensive but you have zero waste --just piece it together. I used a product(closed cell) called "Divinacell" 5/8 thick.

Re: 13' Gheenoe Rebuild

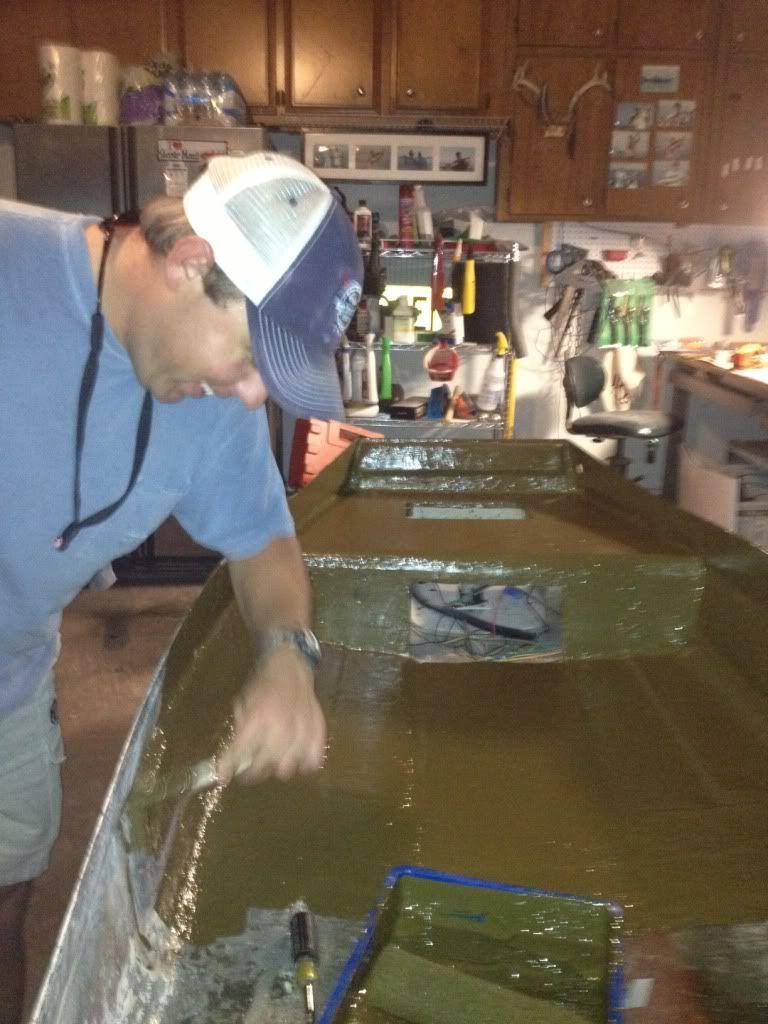

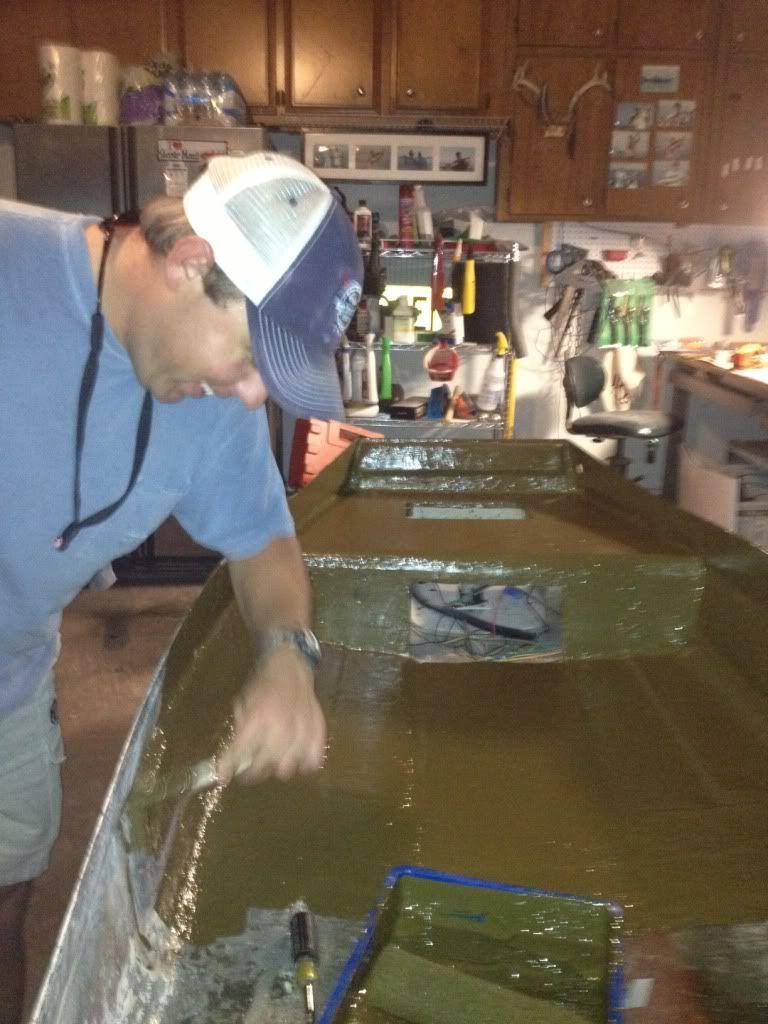

Last night we sanded off most of the remaining gel coat and got to work glassing in the false floor. Before laying the glass down, Jason mixed sawdust and some resin together and made a filler solution that we layed in the gap between the false floor and the deck. After the filler was in, we layed the glass down over it, poured on the resin / hardener solution, and used a paint roller to spread the solution.

Laying the glass down

Making sure it's all down flat

Pouring the resin / hardener on. You also can see the gap where we layed the filler.

Spread it on

Now just waiting on it to dry

We also epoxied in our final piece of false floor last night. Tonight we'll hopefully get the rest of the false floor glassed in and start work on the decks.

Laying the glass down

Making sure it's all down flat

Pouring the resin / hardener on. You also can see the gap where we layed the filler.

Spread it on

Now just waiting on it to dry

We also epoxied in our final piece of false floor last night. Tonight we'll hopefully get the rest of the false floor glassed in and start work on the decks.

Boom goes the dynamite.

-

Salty Gator

- Site Sponsor

- Posts: 3442

- Joined: April 17th, 2010, 7:23 pm

- Location: Tallahassee

Re: 13' Gheenoe Rebuild

Lookin good Casey.

Catholic girl pray for me, you’re my only hope for heaven

Re: 13' Gheenoe Rebuild

Did a bit more work last night. Finished glassing in the other half of the false floor and added some glass to what will be one of the bulkheads for the front deck. Also patched a few thin spots on the inside of the hull.

The false floor is glassed in - we added a drain to the front section of the false floor, but for what we did last night had to remove the drain and glass over the hole. Should be fairly easy to remove the glass over the existing hole.

In hindsight I should've just cut the top half of the bench off instead of removing a rectangular piece from each side. You can see where we've had to epoxy in a new piece of glass to fill that void and then had to add more glass when it didn't fit exactly into the gap. In the center of this pic, you can see the hole that we cut out for the drain.

The false floor is glassed in - we added a drain to the front section of the false floor, but for what we did last night had to remove the drain and glass over the hole. Should be fairly easy to remove the glass over the existing hole.

In hindsight I should've just cut the top half of the bench off instead of removing a rectangular piece from each side. You can see where we've had to epoxy in a new piece of glass to fill that void and then had to add more glass when it didn't fit exactly into the gap. In the center of this pic, you can see the hole that we cut out for the drain.

Boom goes the dynamite.

Re: 13' Gheenoe Rebuild

It's been a month since my last update...work and gator season have gotten in the way of progress on the gheenoe. DCruz and I were finally able to get back to work last night. When we got to the house, Skip had already screwed down both of the decks so they were ready for fiberglass. In our month long sabbatical, Skip has been piddling on the boat and has done some really cool stuff. He's installed a bilge pump, wired the running lights, and even installed an LED light inside the gheenoe so you can see in the bottom of the boat in the dark. Mores pics to come of these improvements, but the two photos below are of us glassing in the front deck.

Spreading the resin / hardener mixture on the glass. We used structural glass in the corners to add more support and then layed chopstrand mat on the flat areas. The corners and extreme angles made the glasswork challenging.

Here's a view from the stern of the boat. We ran out of resin and so after a trip to WM, we'll be back at it this evening to do the back deck.

We've also epoxied in a square-shaped piece of wood on each side of the gheenoe that we plan to glass in tonight. Rod holders will be mounted here and will mainly be used to hold up our duck blind. In the photo you can also see the false floor that I think turned out nicely. We have a stainless drain-hole cover that will be installed once all the glassing and sanding is done as well.

Spreading the resin / hardener mixture on the glass. We used structural glass in the corners to add more support and then layed chopstrand mat on the flat areas. The corners and extreme angles made the glasswork challenging.

Here's a view from the stern of the boat. We ran out of resin and so after a trip to WM, we'll be back at it this evening to do the back deck.

We've also epoxied in a square-shaped piece of wood on each side of the gheenoe that we plan to glass in tonight. Rod holders will be mounted here and will mainly be used to hold up our duck blind. In the photo you can also see the false floor that I think turned out nicely. We have a stainless drain-hole cover that will be installed once all the glassing and sanding is done as well.

Boom goes the dynamite.

Re: 13' Gheenoe Rebuild

The only thing missing is a tuna tower!

Re: 13' Gheenoe Rebuild

And more coors light!!. Good job Casey, that will be a nice boat for all sort of fishing and hunting. I want a ride when finished. I will supply da beer.TallyFish wrote:The only thing missing is a tuna tower!

Re: 13' Gheenoe Rebuild

Got the back deck laid up tonight. Here's a shot of the structural glass prior to adding the resin / hardener mix.

Here's a shot of the deck after we've rolled the resin in. You can also see the LED light we've installed to help see items in the boat in the dark.

Tonight we'll do a little touch up work and then start sanding. After that, we should be able to start rolling gel coat on the inside of the boat.

Here's a shot of the deck after we've rolled the resin in. You can also see the LED light we've installed to help see items in the boat in the dark.

Tonight we'll do a little touch up work and then start sanding. After that, we should be able to start rolling gel coat on the inside of the boat.

Boom goes the dynamite.

Re: 13' Gheenoe Rebuild

We're adding a hatch to the back deck and will be able to access the drain plug through that hatch as well as the bilge pump.lizbeth wrote:where is your access for your drain plug ?

Boom goes the dynamite.

Re: 13' Gheenoe Rebuild

Boy are we getting close to getting this baby finished. Both the decks have been glassed, sanded, and then re-glassed. Yesterday we patched up areas where the first attempt at fiberglassing wasn't pretty.

Because of the steep angle, a large air bubble had formed inside the glass right on the front deck lip. We sanded it down and added more glass and a lot more resin this time.

Skip and I also cut out the front hatch and have it installed for the most part.

Before shot

During the cutting

New look - you can also see the bilge pump that Skip has installed

One final pic with the hatch and the casting platform on the front deck...

Tonight we do a little sanding and apply the first coat of gel coat. Oh yeah, and I go pick up the 15' gheenoe that I bought off Craigslist...this is addictive.

Because of the steep angle, a large air bubble had formed inside the glass right on the front deck lip. We sanded it down and added more glass and a lot more resin this time.

Skip and I also cut out the front hatch and have it installed for the most part.

Before shot

During the cutting

New look - you can also see the bilge pump that Skip has installed

One final pic with the hatch and the casting platform on the front deck...

Tonight we do a little sanding and apply the first coat of gel coat. Oh yeah, and I go pick up the 15' gheenoe that I bought off Craigslist...this is addictive.

Boom goes the dynamite.

Re: 13' Gheenoe Rebuild

Looks great! I'm learning and getting some ideas for the future from your pictures.

Is that a casting deck or an exit ramp on the front? I stand up and fish in my 15 footer pretty easily. The only time I've fallen out was when a seat broke as I was adjusting the motor and I did a back flip over the stern into the cold water. I'm not to sure I'd have the balance to stand up that high on a casing platform and fish though.

I stand up and fish in my 15 footer pretty easily. The only time I've fallen out was when a seat broke as I was adjusting the motor and I did a back flip over the stern into the cold water. I'm not to sure I'd have the balance to stand up that high on a casing platform and fish though.

Is that a casting deck or an exit ramp on the front?

- Gulf Coast

- Site Sponsor

- Posts: 1914

- Joined: February 9th, 2010, 2:25 pm

- Location: WOODVILLE/MEDART

Re: 13' Gheenoe Rebuild

We were able to gel coat half of the boat last night. Only got half done because our fiberglass and resin from the night before hadn't dried yet. Always make sure you use enough hardener...we had to mix up an extra hot batch of resin / hardener and spread it over the still-wet glass and then go over it with a heat gun to make it kick.

We used rollers to spread on the gel coat and then a paint brush to get it in those hard-to-get-to places.

Color is a little darker (dead grass) than I was expecting, but I think it's going to turn out nice.

After we get the inside done with another coat, we're going to tape off the channels and apply a third, lighter colored coat to make it pop. Why do you tape off channels, you might ask (at least I did)? Apparently, it will allow any water in the boat to flow freely to the stern instead of puddling if it was all one flat surface. My consultant, Black Pearl, has me convinced that adding the accents will make the inside look sweet.

One more pic.

One other observation / screw-up that could've been avoided for anyone taking on a project like this - we should've gel coated the area under the back deck before installing the deck. The area remains bare glass in the back and I think it looks ugly. Now it's going to be a PITA to get that area coated correctly.

We used rollers to spread on the gel coat and then a paint brush to get it in those hard-to-get-to places.

Color is a little darker (dead grass) than I was expecting, but I think it's going to turn out nice.

After we get the inside done with another coat, we're going to tape off the channels and apply a third, lighter colored coat to make it pop. Why do you tape off channels, you might ask (at least I did)? Apparently, it will allow any water in the boat to flow freely to the stern instead of puddling if it was all one flat surface. My consultant, Black Pearl, has me convinced that adding the accents will make the inside look sweet.

One more pic.

One other observation / screw-up that could've been avoided for anyone taking on a project like this - we should've gel coated the area under the back deck before installing the deck. The area remains bare glass in the back and I think it looks ugly. Now it's going to be a PITA to get that area coated correctly.

Boom goes the dynamite.